Precision and Speed: The Ultimate Nail Making Machine Solution

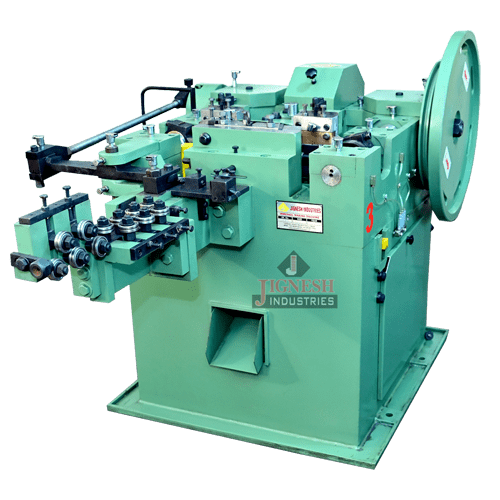

In the world of nail manufacturing, precision and speed are paramount. The demand for nails continues to rise, and manufacturers are constantly seeking innovative solutions to meet this demand efficiently. Enter the ultimate game-changer—the Nail Making Machine. Combining cutting-edge technology with unparalleled craftsmanship, this machine has revolutionized the nail production industry. In this article, we will delve into the features and benefits of this remarkable invention, exploring how it delivers precision and speed like never before.

The Power of Precision:

Precision is the hallmark of exceptional nails, and the Nail Making Machine excels in this area. Equipped with advanced engineering and meticulous design, this machine ensures that every nail produced is of the highest quality. The automated process leaves no room for error, guaranteeing consistent dimensions, smooth finishes, and accurate shapes. With precision at its core, this machine eliminates the need for manual labor, reducing human error and increasing overall productivity.

Unleashing Speed:

Speed is a crucial factor in meeting the ever-growing demand for nails. Traditional nail production methods can be time-consuming, resulting in a bottleneck in the manufacturing process. The Nail Making Machine, however, has changed the game by offering unparalleled speed. With its automated mechanism, this machine can produce an impressive number of nails in a fraction of the time compared to manual methods. Manufacturers can now meet deadlines and exceed customer expectations with ease, propelling their businesses to new heights.

Advanced Technology for Efficiency:

The Nail Making Machine harnesses the power of advanced technology to streamline the production process. Featuring state-of-the-art components and intelligent systems, it optimizes efficiency, minimizing waste and maximizing output. From wire feeding and cutting to nail forming and polishing, every step is seamlessly integrated, resulting in a smooth and efficient workflow. The machine’s user-friendly interface allows operators to monitor and control the entire process, ensuring optimal performance and ease of operation.

Versatility and Customization:

One of the key advantages of the Nail Making Machine is its versatility and customization options. It can produce a wide range of nail types, including common nails, finishing nails, roofing nails, and more. By simply adjusting the settings, manufacturers can customize the nail length, diameter, and head shape according to their specific requirements. This flexibility empowers businesses to cater to diverse market demands, expanding their product offerings and increasing customer satisfaction.

Enhanced Safety and Sustainability:

In addition to precision and speed, the Nail Making Machine prioritizes safety and sustainability. The automated process significantly reduces the risk of accidents and injuries associated with manual nail production methods. Moreover, this machine promotes sustainability by minimizing material waste and energy consumption. With its efficient design and optimized resource utilization, it aligns with the growing emphasis on eco-friendly practices in the manufacturing industry.

Conclusion:

Precision and speed are the driving forces behind the success of any nail manufacturing business. The Nail Making Machine offers the ultimate solution, combining cutting-edge technology, precision engineering, and unmatched efficiency. With its ability to deliver high-quality nails at a remarkable pace, this machine has transformed the industry. Manufacturers can now meet market demands, enhance productivity, and stay ahead of the competition. The future of nail production lies in the precision and speed of the Nail Making Machine, shaping a new era of efficiency and excellence.