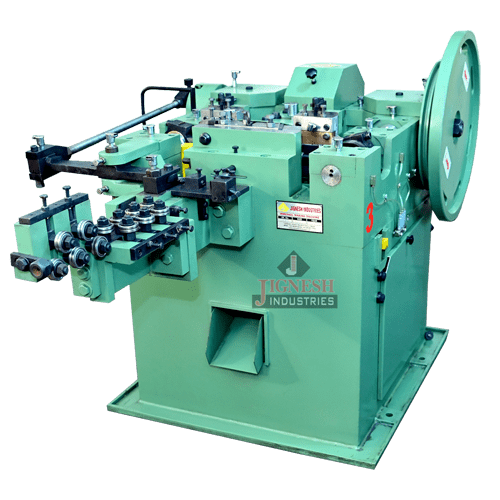

Wire Nail Making Machine

In the world of construction, manufacturing, and carpentry, nails are an essential component that holds everything together. Traditionally, nails were made by hand, a time-consuming and labor-intensive process. However, with the advent of technology, wire nail making machines have transformed the nail production industry. These machines automate the nail manufacturing process, increasing efficiency, precision, and productivity. In this article, we explore the workings and benefits of wire nail making machines and how they have revolutionized the way nails are produced.

Automation and Speed:

Wire nail making machines have replaced the manual labor previously required to produce nails. These machines are equipped with advanced mechanisms that automate the entire manufacturing process. They can efficiently and rapidly convert wire coils into nails, significantly increasing production speed. With the ability to produce thousands of nails per minute, wire nail making machines have revolutionized the manufacturing industry by streamlining the production process and meeting the ever-increasing demand for nails.

Precision and Consistency:

Consistency and precision are crucial factors in nail production. Wire nail making machines ensure that every nail produced adheres to the desired specifications. These machines are designed to cut wire coils to precise lengths, form heads with accurate dimensions, and sharpen points with consistent angles. This level of precision ensures that the nails fit securely, provide reliable structural support, and enhance the overall quality of construction and carpentry work.

Versatility and Customization:

Wire nail making machines offer versatility and customization options to meet diverse requirements. These machines can be adjusted to produce nails of different sizes, shapes, and materials. From common nails to specialized types like finishing nails, roofing nails, or concrete nails, wire nail making machines can accommodate various nail profiles. This versatility enables manufacturers to cater to specific industry needs and provides flexibility for customized nail production.

Cost Efficiency and Waste Reduction:

Implementing wire nail making machines brings significant cost savings to nail manufacturers. With automation, labor costs associated with manual nail production are significantly reduced. Moreover, these machines optimize raw material usage by minimizing waste. Wire nail making machines have efficient cutting mechanisms that ensure minimal material loss during the manufacturing process. This waste reduction translates into cost savings and promotes sustainability by minimizing environmental impact.

Enhanced Safety and Ergonomics:

Wire nail making machines prioritize safety and ergonomics in nail production. By automating the manufacturing process, these machines eliminate the need for manual handling of sharp wire coils, reducing the risk of injuries. Additionally, they incorporate safety features such as emergency stop buttons and protective guards to ensure a safe working environment for operators. The ergonomic design of wire nail making machines also minimizes operator fatigue and strain, enhancing productivity and overall workplace well-being.

Conclusion: Wire nail making machines have revolutionized the nail production industry by offering automation, precision, versatility, and cost efficiency. With their ability to rapidly produce nails of consistent quality, these machines have become indispensable in the construction, manufacturing, and carpentry sectors. By embracing this technology, nail manufacturers can streamline their operations, meet growing demand, and deliver high-quality nails that contribute to safe, reliable, and durable construction projects. The advent of wire nail making machines has ushered in a new era of efficiency and productivity in nail production, transforming the way nails are manufactured worldwide.